A type of material composed of natural or synthetic fibers. Types

of textiles include animal-based material such as wool or silk,

plant-based material such as linen and cotton, and synthetic material

such as polyester and rayon. Textiles are often associated with the production of clothing. fabric: cloth or fabric that is woven, knitted, or otherwise manufactured. Raw material used for making fabrics: raw material that is used for making fabrics, e.g. fiber or yarn.

A

Abaca

A hemp like fiber used for cordage grown in the Philippine Islands.

Abrasion

The wearing away of fiber by rubbing away.

Absorbency

The ability of a fiber or fabric to absorb moisture.

Acetate

A manufactured fiber that uses cellulose refined from cotton and/or wood pulp. Characteristics: fast drying, wrinkle- and shrinkage-resistant, crisp or soft depending on end use, luxurious in appearance.

Acid Dye

A dye which is applied to protein fabric or fiber from an acid dye solutions. It can be used on nylon, wool and other animal protein fibers, silk, acrylic, polypropylene and blends. It is fairly colorfast to light and laundering.

Acrylic

A manufactured fiber made from long-chain synthetic polymers. Characteristics: wrinkle resistance; low moisture absorbency and quick-drying; provides warmth yet lightweight, soft and resilient.

Adjective Dye

A dye which requires the use of mordents. See natural dyes.

Akha Spindle

A lightweight, supported spindle.

Aklae

Norwegian low-warp tapestry technique. Wefts interlock between two warp ends.

Alpaca

Specialty hair fiber from the alpaca, a member of the South American llama family. It is softer, finer, more lustrous and stronger than sheep's wool, but in relatively short supply. Fibers are prized for their strength, durability and beauty. Please see McColl's Darkroom in Cyberspace for drawings showing a close-up of fiber.

Alum

Hydrated double-sulfate of alumina potassium. A commonly used mordant.

Albegal SET

Liquid dyeing assistant for Sabraset/Lanaset Dyes, used to obtain level colors.

Amercian Pima Cotton

A cross between Sea Island and Egyptian cotton. Grown in Arizona. Length averages 13/8" to 15/8".

Ammonia

An alkaline liquid used in natural dyeing.

Ammonium Sulfate

A mild acid-forming salt used with acid dyes. Used to insure levelness for light to medium shades.

Anti-chlor Concentrate

A sodium bisulfite compound used to neutralize residual chlorine when removing color with hypochlorite bleach.

Aniline Dyes

A class of synthetic, organic dyes originally obtained from aniline (coal tars),and were the first synthetic dyes. Today the term is used with reference to any synthetic organic dyes and pigments, in contrast to animal or vegetable coloring materials, and synthetic inorganic pigments. Aniline dyes are classified according to their degree of brightness or their light fastness. Also called "coal tar dyes."

Animal Fibers

Protein-based hair, fur, and cocoon materials taken from animals. Typical animal fibers include, wool, mohair, llama, alpaca, cashmere, camel and vicuna and cocoon material (silk).

Angora

Downy soft, fluffy hair that is plucked or sheared from the angora rabbits. This is a slippery, flyaway fiber is usually blended with wool or other fibers to make it easier to spin and to reduce the cost.

Angora Goat

The goat that produces "mohair"

Anthrax

A highly dangerous, infectious disease cased by Bacillus anthracis. In humans, a form of this disease is commonly called "wool sorter's disease". It may be contracted, most likely through skin abrasion from handling fleeces from infected animals. More information about this disease may be found at the HealthScout's site.

Apparel Wool

All wools that are manufactured into cloth for use as clothing.

Attenuation

In spinning, the fibers are pulled out of a distaff or from a ball of roving into a strand of the desired diameter.

Axle

This is the metal shaft through the center of wheel, supporting it. There is usually a set screw that 'locks' it in place which (sadly) can be sheared off.

B

Baby Combing WoolShort, fine wool which is usually manufactured on the French system of worsted manufacture. This term is synonymous with "French Combing Wool". Backcross

The mating of a crossbred animal to one of the parental breeds.

Bactrian Camel

The Bactrian camel is the camel that camel hair comes from.

Bags

In the United States, the commercial wool growers have their fleeces loaded into large cloth bags for shipping to the wool mills. In Australia and New Zealand, the fleeces are packed into "bales" -- which load better in the ship holds for export abroad.

Balanced

A plied yarn that doesn't twist back on itself. If you hold ~10 inches of yarn by the ends, then slowly move your hands closer together until they are ~2 inches apart, a balanced yarn will drape itself into an elongated U. An over-spun yarn will ply back on itself.

Bales

In countries where the fleece traditionally has been shipped, the fleeces are packed into bales -- which load better in the ship holds for export abroad. Depending on the country, the bales weigh different amounts. Australian and New Zealand bales weigh 150 kg (330 lb), whereas South American bales weight approximately 1,000 lb (454 kg).

Cotton also is shipped in 500-pound bales.

Basic Dyes

A class of dyes, usually synthetic, that act as bases, and which are actually aniline dyes. Their color base is not water soluble but can be made so by converting the base into a salt. The basic dyes, while possessing great tinctorial strength and brightness, are not generally light-fast.

Basket Weave

A variation of the plain weave in which two or more threads weave alike in both warp and weft, joined in the regular order of the plain weave. Named for the basket-like pattern of the weave.

Bast Fibers

Fiber obtained from the stems of certain types of plants. These include flax, hemp, jute, ramie, milkweed, and nettles.

Batik

A traditional dyeing process in which portions of cloth are coated with wax and resist the dye.

Batt or Batting

Sheets or rolls of carded cotton or wool or other fiber or mixtures thereof which is used for woolen spinning or for stuffing, padding, quilting, and felting.

Bead Yarn

A yarn upon which is fastened either an actual bead or (commercially) a lump of hardened gelatine of a bead-like form.

Belly Wool

The wool that grows on the belly of the sheep and occasionally extends up the side in irregular patches. It is usually an uneven, different grade from the body of the fleece. It is shorter and less desirable because of its poor lock formation, and it usually lacks the character of the body of the fleece.

Beetle

A large wooden mallet used to help soften cellulose fibers. Often used with linen and ramie.

Beetling

The process of striking woven linen or ramie fabric with rollers to flatten the fibers. This leaves you with a more lustrous fabric.

Belly Wool

The short, and often weaker, fiber from the sheep's belly. It should be skirted off.

Binders

The individual hairs in a sheep's fleece that run from one staple to another.

Binding Threads

Threads used to unite two or more ply into one firm (stable) structure.

Black Wool

Any wool containing non-white fibers. A fleece having only a few black fibers is rejected by a grader and goes into the black wool bag because there is no way of separating the few black fibers in the manufacturing processes. Black wool is usually run in lots that are to be dyed.

Black-top Wool

Wool containing a large amount of wool grease combined at the tip of the wool staples with dirt, usually from a Merino. This wool is usually fine in quality, of good character, and desirable in type, but the shrinkage is high.

Bleaching

The procedure, other than by only scouring, of improving the whiteness of textile materials. Sometimes accomplished with and sometimes without the removal of natural colouring or other extraneous substances.

Bleeding

A term applied to yarn from which the color runs, usually staining the white or lighter colored-items nearby.

Blend

A textile containing two or more different types fibers or different colors and grades of the same fiber.

Blocker

A frame for drying wool. A fine picture of one can be found at the CyberFiber site. This is a open frame that rests on two supports with a handle on one side. You wind the damp yarn under even tension across the frame -- not trying to line anything up. Rather like winding a bobbin for weaving. After the yarn dries, you can usually slide the whole skein off of one end. Edward Worst's book "How to Weave Linens" has directions for making a blocker. Sadly, this book is out of print.

Blocking

The process of drying a skein of wool under tension. This can be done by drying a skein on a blocker. More prosaically, it can done by winding around an upended-chair's legs or by hanging a weight in the bottom of a skein. A #2 can of tomatoes is often used as you don't get a sharp crease.

Blood or Blood Grade

This refers to the fineness of the wool, measured as low 1/4, 1/4, 3/8, and 1/2 blood. It reflects the amount of Merino blood in a breed. 'More blood' refers to a larger amount of Merino in a sheep which should produce a finer wool. Please see Wool Grades.

Blowout Factor

The rapidity with which an animal's fiber diameter thickens with age. (A bad thing.)

Bobbin

Bobbins The cylinder or spool upon which yarn or thread is wound. An option to buying lots of bobbins for your wheel is using "Storage Bobbins".

Bobbin Lead

A single band drives the bobbin. The flyer has a friction brake. A well-known example of this would be the Ashford Traditional. Another term used is "Scotch Tension".

Boculè

A compound yarn comprising a twisted core with an effect-yarn wrapped around so as to produce loops on the surface.

Body

A term applied to wool when the staple has a good "hand" (full and with bounce). It can also refer to the fullness of a fabric. This is a subjective quality and has to do with a lack of limpness and/or stiffness. A fabric is said to have a good body when it has a full, rich, and supple hand.

Boiled Wool

Thick, dense fabric that is heavily fulled to completely obscure its knitted construction.

Boiling Off

The operation of removing, by means of a hot, mildly alkaline liquid, the gum (seracin) which covers the raw silk fiber. Also called "de-gumming".

Bold

I saw one definition that said, "A term applied well-grown wool of good character." Can you have wool with a bad character, i.e., from a bad neighborhood? I suspect that this is another one of those nebulous terms that apply to the wool's "hand".

Botany Wools

Originally referred to merino wool shipped from Australia's Botany Bay. It has become a generic term used to describe superlative wools and fine worsted sweaters.

Bradford Count or Bradford System

The British standard is based on the Bradford Spinning Count System. This originated in the 19th century and is based on the number of 560-yard worsted skeins that can be produced from one pound of clean wool. The clean wool is then thoroughly oiled which aids in producing a smooth, lustrous yarn for suiting. With this system the larger number will be a finer wool. Please see wool grades.

Braid Wool

The coarsest of the U.S. grades of wool, according to the blood system of classification. It is a very coarse and lustrous wool. Please see wool grades.

Break

Weak at a certain point, but strong above and below the weak spot, as opposed to "tender", which signifies a generally weak fiber. This can be caused by a sudden change in pasture, feed, illness, or lambing. Please see McColl's Darkroom in Cyberspace for drawings showing a close-up of fiber. Please also see: "Testing the Wool".

Breaking

Also known as "scrutching". In breaking, the flax plants that have been through the "retting" process pass through rollers or are beaten with a wooden blade to help 'break' the stronger parts without damaging the longer fibers.

Breaking Length

A measure of the breaking strength of a yarn. It is the calculated length of yarn which equals its breaking load and is equal to the tensile stress at rupture of the yarn.

Breaking Load

The maximum stress needed to rupture a fiber, yarn or fabric in a tension test.

Breech or Britch Wool

Wool from the thigh and rear region of the sheep. It is the coarsest and poorest wool on the entire fleece. It is usually manure-encrusted and urine-stained fiber. It should be "skirted" and removed from a fleece for a hand spinner.

Breed Characteristics or Breed Type

Individual breeds have distinct characteristics. A Merino is very fine, shows a lot of crimp, and the fibers are very close. A Lincoln, is much coarser with low crimp.

Bright

Very white, almost reflective, wool relatively free of dirt and sand. Some breeds, like Cormo, are known for producing particularly bright fleeces.

Britch

This is the short, curly fibers found in the groin and belly area of sheep. It has a very different character from the rest of the fleece and should be skirted out. In a perfect world, spinners would never see this.

Brittle

Brittle refers to harsh, dry, 'wire-like' fiber; much like the split ends in hair.

Broadcloth

A fine, closely woven, lustrous cotton or cotton/poly blend made in plain weave with a fine rib in the weft. The filling yarn is heavier and has less twist than the warp. The cloth is usually mercerized, and has a soft, firm finish.

Brocade

Brocade is a jacquard weave with an embossed effect and contrasting surfaces. Can also be woven with synthetic or man-made fibers.

Brushed Wool

Finished yarn or material that has been brushed to raise all loose fibers to the surface, i.e., the commercially-spun mohair yarn.

Buck Fleece

A fleece from a ram. The wool usually has a heave shrinkage due to excessive wool grease; thus wool of this type is not worth as much in the grease as a similar wool from ewes or wethers. Some buck fleeces have a distinctive odor that many find objectionable.

Bulk Grade

The largest percentage of grade in a lot of original-bagged wool.

Bulky

In wheels, a term used for a wheel with a wide orifice. This allows the creation of a thicker yarn suitable for blanket wefts.

Bump

A cylinder of coiled, prepared fibers ready for spinning. This is how commercially prepared fibers are delivered. Rather like if you had access to a really big ball winder and used it to wind the top you had just hand combed.

Burry Wool

Wool heavy in vegetable matter -- including burs, leaves, seeds, and twigs, which requires special and expensive processing in removal.

Bursting Strength

The mechanical test done commercially on fibers to show how strong they are.

C

Cabled YarnTwo or more plied yarns twisted together. One or more part of a cabled yarn can be a single. So if you took two 2-ply and plied them again, you would have a cabled yarn. It is important to remember that you reverse the twist for each step. So if you spun your singles Z, the 2-ply would be spun S, and the cabled yarn would be produced by plying Z. You will need to have extra twist in the singles and the first ply to produce a "balanced yarn". Please check Mabel Ross' book "Essentials of Yarn Design for Hand spinners" for detailed directions.

A 3-2 cable refers to three 2-ply. Calendering

The process of passing fabric through a machine consisting of heavy rollers which rotate under pressure to smooth and flatten fabric, to close the intersection between the yarns, or to confer surface glaze. (Often used with cellulose fibrics like linen and cotton.)

Camel's Hair

Hair from the two-humped Bactrian camel, which is softer, lighter in weight and more fragile than wool. It provides warmth without weight, it never wrinkles and is water repellent.

Camelid

Any animal that comes from the camel family. Obviously camels, but also alpaca and llama.

Canary-stained Wool

A yellowish coloration in the wool which cannot be removed by ordinary scouring methods. May be caused by bacterial growth or urine staining.

Candle

This refers to the stiffened fat on an unwashed fleece. Not a pleasing condition for Hand spinners and often a condition when fleeces sit for years waiting to be spun.

Canvas

A general classification of strong, firm, closely woven fabrics usually made with cotton. A heavier, open weave comprised of plied yarns. Characteristics: very hard-wearing, generally water-resistant.

Carded Fibers

Fibers that have been carded which opens them up.

Carbonizing

The process of treating wool with chemicals, usually acids, to destroy and remove the burrs without seriously damaging the wool. The usual chemical used is sulphuric acid. Wool so treated is known as carbonized wool.

Carders

Also known as hand carders (as opposed to "drum carders"). Some of the carders have curved backs, some straight backs. There is some belief that the reason why modern hand cards have the curved backs is because they were modeled after museum pieces. Unfortunately, the museum pieces were warped (curved). Early plans for carders show the straight backs.

Now, having said that, let me add that if you like using curved-back cards, you should do so. I have a pair of Ashford hand cards (with curved backs) that I just love. As much hand carding as I do, this isn't a problem for me.

A more critical requirement is that your cards have offset handles. This will save wear-and-tear on your hands.

Carding

Carding is the process used to open out fleece so that it can be more evenly spun into a "woolen" yarn. The process by which the fibers are opened out into an even film. The etching, La Cardeuse (The Wool Carder), shows a woman carding with flat-backed carders. And, Celerina's site has an animation showing hand carding.

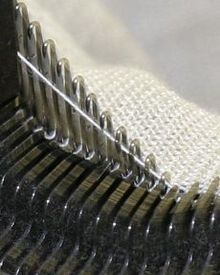

Carding Cloth

The Woolly Designs site has a close-up of Carding Cloth. The material is used on hand cards, drum carders, and carding boards. The spacing of the tines causes it to be classified as 'fine' or 'coarse'. Many manufacturers refer to their combs as 'cotton cards' or 'wool cards'.

Carding Wools

Wools that are too short to be treated by wool combing and must be processed into woolen yarns. Synonymous with "clothing wool".

Carpet Beetle

The larvae of this beetle eats wool and other protein fibers. Various articles on fiber pests can be found here.

Carpet Wool

Coarse, harsh, strong wool that is more suitable for carpets than for fabrics. Very little of this type is produced in the U.S. Some of the choicer carpet wools are used to make tweeds or other rough sport clothing. Some breeds, like Karakul, are mainly used for rugs.

Cashgora

Fiber produced by crossing cashmere goats with angora goats.

Cashmere

Soft, silky fiber combed from the cashmere goat with a diameter of 18.5 microns or less. Cashmere has excellent insulating power, providing warmth without weight or bulk. It drapes beautifully, resists wrinkles, and sheds lint. Costly because of limited supply.

Castle Wheel

The flyer is usually mounted above the wheel, which means less floor space is used. A well-known example of this is the Castle Wheel at Alden Amos' site.

Cellulose Fiber

Or cellulosic fiber. Fibers produced form the cell walls of plants, i.e., cotton, hemp, ramie.

Chaffy Wool

Wool containing a considerable amount of chaff -- finely chopped straw.

Chambray

A general class of plain weave, usually cotton, made with a colored warp and white weft.

Character

The evenness, distinctiveness, and uniformity of crimp characteristic of their respective wool classes. A well-bred wool of 'good character' will usually show a pronounced crimp and distinct staple formation.

Charka

Charka (means wheel) was developed in India by Ghandi in early 1920's so the people of India could spin cotton thread and not be dependent on foreign materials. A wonderful description of the 'Khadi' or 'Swadeshi' movement can be found in "A philosophy... handspun" by G. Janani at the Hindu.com site.

The book-size Charka is a mobile, self-contained charka. Charkas are designed for spinning fine fibers such as cotton, silk, angora, and cashmere, etc.

Charmeuse

Charmeuse is a satin weave silk with a crepe back sometimes called crepe-backed satin.

Cheeses

Cheeses refer to the spirals of pencil roving produced on the large mechanized carders. The fibers can be knit as is (the original Lopi®) or can be spun up.

China Grass

An alternative name for ramie, a bast fiber.

Citric Acid Crystals

Substitute for Acetic Acid 56%. Use 1 teaspoon to replace 1 teaspoon Acetic Acid 56%.

Class-one Wool

Merino sheep produce the best wool which is relatively short, but the fiber is strong, fine, and elastic and has good working properties. Merino fiber has the greatest amount of crimp of all wool fibers and has a maximum number of "scales": two factors which contribute to its superior warmth and spinning properties. These sheep produce class one wool.

Class-two Wool

Class-two wools are not quite as good as the Merino wool, but this variety is nevertheless a very good quality wool. It is 50-200 mm in length, has a large number of "scales", and has good working properties. This class of sheep originated in England, Scotland, Ireland and Wales.

Class-three Wool

These fibres are about 100-455 mm long, are coarser, and have fewer "scales" and less crimp than Merino and Class-two wools. As a result, they are smoother, and therefore, they have more lustre. These wools are less elastic and resilient. They are nevertheless of good quality to be used for clothing. This class of sheep originated in the United Kingdom.

Class-four Wool

These fibres are from 25-400 mm long, are coarse and hair like, have relatively few "scales" and little crimp, and therefore, more smoother and more lustrous. This wool is less desirable, with the least elasticity and strength.

Classification by Fleece

Wool shorn from young lambs differs in quality from that of older sheep. Also, fleeces differ according to whether they come from live or dead sheep, which necessitates standards for the classification of fleeces.

Clean Content

The amount of clean, scoured wool remaining after removal of all vegetable and other foreign material.

Clean Wool

Usually refers to scoured wool but occasionally it describes grease wool that has a minimum amount of vegetable matter.

Clear Finishing

Usually, worsteds are not brushed, but closely sheared to give the fabric a clean face and crisp feel. This is called clear finishing. See also "unfinished worsteds.

Clip

With angora goats, refers to the amount of hair removed from a single animal.

Clock Reel

A device for winding hanks of yarn. Some come with various kinds of counters. An image of a clock reel can be found at the Illinois State Museum site.

Clothes Moth

The larvae of this moth eats wool and other protein fibers. Various articles on fiber pests can be found here.

Clothing Wool

(Industry Term) Wool under 1.5 in. in length and distinguished from combing wools by their shorter length. Principal properties include softness, crimpiness, and felting ability; see also "carding wool".

Cloud Yarn

A term given to yarns of irregular twist obtained by alternately holding one of the component threads while the other, being delivered quickly, is twisted around it, and then reversing the position of the two threads; thus producing alternate clouds of the two colors.

Cloudy Wool

Wool that is off-color. It may be due to wool becoming wet while poorly stored in a pile.

Coarse Wool

Wool that has a Blood grade of 1/4 or Common OR a numerical count grade of 44's, 45's, or 48's, OR a micron count above 31. Coarse wool may have as few as 1 to 5 crimps per inch.

Coated Fleeces

Some wool producers coat their fleeces that cut down on the amount of vegetable matter and weathering. Some images, from Gleason's Fine Woolies, show coated sheep.

Color Fastness

The term used to describe the resistance of fabric to the loss of color. There are several things which can cause loss of color, the most important being washing and light.

Collapse Yarn

Collapse yarn is (usually) an over spun single, dried under tension (see "blocking") that is then knit or woven. When the item is moistened, the yarn returns to its original elastic state. See "balanced yarn".

Color

The actual color of the wool. In industry a bright white to cream is most desirable; canary stains, brown or black stains are undesirable.

Color Defect

Any color that is not removable in wool scouring, due to urine stain, dung stain, canary yellow stain, or black fibers.

Color Fastness

That property of a dye, to retain its original hue, when handled under normal conditions when exposed to light, heat, or other conditions.

Combed fibers

Fibers that have combed. This process removes the short fibers. When drawn off, the fiber is called "top".

Combing

An operation in the worsted system of fiber preparation that removes the short fibers (see "noil", "second cuts") and foreign impurities. The long fibers are straightened and laid parallel. See also "wool combs" and "worsted preparation".

Combing, Dry

The preparing and combing of wool to which no oil has been added.

Combing in Oil

The preparing and combing of wool to which oil has been added to facilitate the manipulation of the fibers.

Combing Wool

Wools having sufficient length and strength to comb. According to industry standards, the length of fibers for strictly fine combing must be over 2.75 in., with an increase in length as the wool becomes coarser.

Common

One of the U.S. Grades of wool. It is next to the coarsest grade, and derives its name because it presumably comes from sheep of common ancestry.

Complements

These are colors that are opposite one another on the hue circle.

Condition

In grease wool, the amount of yolk and foreign impurities it contains A fleece having a "heavy condition" would have a large amount of shrinkage.

Consistency

The uniform distribution of all the fiber characteristics within each lock and throughout the entire fleece.

Copp

This refers to the cone of fibers that builds up on a spindle.

Corduroy

A strong, durable fabric with cotton ground and vertical cut-pile stripes (wales) formed by an extra system of filling yarns. The foundation of the fabric can be either a plain or twill weave.

Core-testing

The coring of bales or bags of wool to determine the clean content (or "condition") and yield.

Core Yarn

A yarn made by winding one yarn around another to give the appearance of a yarn made solely of the outer yarn.

Cortical Cells

The spindle shaped cells forming the inside structure of a fiber.

Cotted

A fleece that contains fibers that are matted (or "felted") together.

Cotton

A cellulose fiber collected from the perennial shrub from the genus Gossypium; predominantly G. hirsutum (upland or long-staple cotton), but also some G. barbadense (Pima or extra-long-staple cotton). A vegetable fiber consisting of unicellular hairs attached to the seed of the cotton plant. Most cotton is colored a light to dark cream, and its chemical composition is almost pure cellulose. Colored cottons in shades of tan, greens, blue, and rust are also less commonly available. A distinct feature of the mature fiber is its spirality or twist. For more information on cotton, you might want to look at: "Queen Cotton" by Susan Druding from the Textile Arts Forum.

Cotton Count

The cotton count expresses the number of hanks required to make a pound of yarn. A hank of cotton is equal to 840 yards. So 1 cc = 840 yards of cotton, the coarsest cotton yarn. A 3 cc yarn would then be one third as course and would be expressed as 3/1 cc show that it is a single strand. Likewise plies are designated by two numbers separated by a slash such as 4/2 cc. This equals 3360 yards (4 x 840) of two-ply yarn. This yields 1680 yards of yarn per pound (3360/2). An 8/4 cc yarns would yield the same number of yards per pound, but would be a 4 plies of finer yarn. So a Number 8 four-ply yarn is the same diameter as a Number 4 two ply yarn.

Cotty Wool

Wool that has matted or felted on the sheep's back. Caused by insufficient wool grease being produced by the sheep, usually due to breeding, injury, or sickness. This type of defective wool is more common in the medium to coarse wools. The fibers cannot be separated without excessive breakage in manufacturing.

Count

The number given to a yarn of any material, usually indicating the number of hanks per pound of that yarn. May also refer to the fineness to which a fleece may be spun. There are at least three definitions. In raw wool, a number used to indicate fineness, see "micron count". In worsted yarn, the number of 560-yard skeins weighing one pound (Bradford method). In woolen yarn, the number of 256-yard skeins weighing one pound (Yorkshire method).

Crabbing

A term used in the textile industry. Crabbing sets the cloth and yarn twist by rotating the fabric over cylinders through a hot-water bath, or through a series of progressively hotter baths, followed by a cold-water bath. Crabbing is done to stabilize the fabric before dyeing and finishing and is necessary only for worsted fabrics.

Crank

The extension of the "axle" to the "footman".

Crease-Resistant

This refers to the ability of a fabric to resist and recover from creasing during use. Wool is considered to be very crease resistant, while cotton is not. And don't even get me started on linen!

Crepe

A general classification of fabric characterized by a broad range of crinkled or gained surface effects. Methods of making crepe include the use of hard twisted yarns, special chemical treatment, special weaves and embossing.

Crimp

The wave effect in the wool fiber. Usually the finer wools show the most crimp. Uniformity of desired crimp generally indicates superior wool.

- distinct

- refers to crimps that are sharp and clear -- fine wools have more crimps per inch

- bold

- larger crimp refers to spaces widely apart -- coarser wools have fewer crimps per inch.

The ability of a yarn or fiber to return to its original crimped state after being released from a tensile force.

Crocking

The name given to when excess dye rubs off from fibers.

Crinkle

The waviness of each individual fiber when separated from a lock. It is responsible for elasticity and is usually irregular.

Croop

Silk, especially after immersion in a weak acid, when compressed and rubbed, gives out a peculiar rustling sound, which is known as 'croop'.

Crocking

The transfer of dye stuff from one fabric to another item by friction. This usually happens when a fabric or yarn has been overdyed.

Cropping

The process of cutting the pile on a fabric to uniform height or cutting loose fibres from the surface of a cloth after weaving.

Crossbred or Cross Bred

Wool produced by crossing different breeds of sheep.

Curl Yarn

A type of yarn which presents curls or loops of various sizes all along its surface. It is usually produced as follows: Two threads, a thick and a thin are twisted together, the thin being held tightly and the thick thread slackly twisted around it. This two-fold yarn is then twisted in the reverse direction with another thin thread, this untwisting throwing up the thick thread as a loop, the two fine threads holding the loops firmly.

Cuticle

The outer layer of cells of a fiber which are hard, flattened and do not fit together evenly and whose tips point away from the fiber shaft forming serrated edges. These serrated edges cause the fibers to grip together during processing and manufacturing. See also "scales".

Crossbred Wool

A sheep bred from two distinct breeds; also a classification for wool of medium fineness. In the U.S., wool obtained from sheep of long-wool x fine-wool breeding. Usually this wool grades at 3/8 or 1/2 blood. Please see Wool Grades.

Crutched Wool

Wool that has been clipped from rear end and udder area of ewes in the early spring to prevent collection of manure and fly strike.

D

Damp WoolWool that has become damp or wet before or after bagging and may mildew. This weakens the fibers and seriously affects the spinning properties. Doubling

The process of combing by twisting together two single yarns to form a double yarn.

Doupion

A silk-breeding term used for double cocoons. It is also used to refer to the rougher quality of silk.

Dead Wool

Wool taken from the sheep that have died on the range or have been killed. Wool recovered from sheep that have been dead for some time is occasionally referred to as 'merrin'. Wool taken from sheep that have died on the range or have been killed. Dead wool fiber is decidedly inferior in grade and is used in low-quality cloth.

Decitex

A unit of weight indicating the fineness of yarns and equal to a yarn weighting one gram per each 10,000 meters. The abbreviation for this is "d'tex".

Defective Wool

Wool that contains excessive vegetable matter, such as burs, seeds, and straw, or which is kempy, cotty, tender, or otherwise faulty.

Degreasing

Any method that removes yolk, suint, and dirt from wool.

Degumming

The boiling-off of silk in silk and hot water, in order to dissolve and wash away the natural gum (seracin) which surrounds the fiber.

Delaine Wool

Fine, strictly combing wool, usually from Ohio and Pennsylvania. Delaine wool does not necessarily have to come from the Delaine-Merino; however, that breed is noted for this class of wool.

Demi-lustre Wool

Wool that has some luster but not enough to be classed as luster wool. Wool of this type is produced by the Romney and similar breeds.

Denier

A unit of weight indicating the fineness of fiber filaments and yarns, both silk and synthetic, and equal to a yarn weighting one gram per each 9000 meters; used especially in indicating the fineness of women's hosiery. The abbreviation for this is "d" or "D".

Denim

A well-known basic cotton or blended fabric in a right- or left-hand woven twill. Generally, the warp is dyed blue with a weft.

Density

An index of the number of wool fibers per unit of a sheep's body. Fine-wool breeds show greater fleece density than the coarser wool breeds.

Dingy

Wool that is dark or grayish in color and generally heavy in shrinkage. May be caused by excessive yolk, poor farming conditions, or parasites.

Direct Dyes

A class of aniline dyes, so called because they have such great affinity for cellulose fibers, i.e., cotton and linen. While both these and acid dyes are sodium salts of dye acids, direct dyes do not require the use of a mordant. Their shades are duller than those of either acid or basic dyes and they tend to have less tinctorial value than the basic dyes; however, they have the very important advantages of being much more lightfast than the basic dyes and possibly more so than acid dyes.

Direction of Twist

(S twist or Z twist) To determine twist, hold yarn in a vertical position and examine the angle of the spiral. The angle of the S twist will correspond to the center portion of the S. The angle of the Z twist will correspond to the center portion of the Z. When spinning, the wheel should rotate counter clockwise for an S twist and rotate clockwise for a Z twist.

Dirty Tips

The weathering that occurs on the ends of some locks. These may not completely wash out or evenly dye.

Distaff

A staff with a cleft or formed-end for holding flax from which the fiber is drawn in spinning. May be attached to a spinning wheel. The Monastic Heritage Museum shows a wheel-mounted distaff on a wheel from the 1800's.

Diz

The small tool that is used to help form and even top in wool combing. Traditionally a diz was made out of carved horn. You can also make (or buy) very nice ones out of wood. A cheap, none-classy alternative is to trim a piece of plastic and punch or drill a hole in the middle of it. I've seen this done with the bottom corners of a plastic milk jug or a crescent cut from a section of PVC pipe. As always, if it involves worsted spinning, please see "Hand Woolcombing and Spinning" by Peter Teal.

Dobby

A general term for a fabric woven on a special dobby loom, which allows the weaving of small, geometric figures. A dobby weave can often be distinguished from a plain weave by the patterns are beyond the range of simple looms.

Doggy

Wools that have no character and show the results of lack of breeding. These wools are usually short, coarse, and lacking in feel.

Doff

To remove, as in doffing a drum carder.

Domestic Wools

All wools grown in your own country as opposed to those imported.

Double Drive

Both the flyer and bobbin are driven by belts from the drive wheel. The bobbin pulley (or whorl) is smaller, which determines the spinning ratio. Some double drive wheels can be converted to run with Scotch Tension.

Double Coated

Some breeds of sheep (and other fleece-bearing animals) have two coats. Sometimes the double-coating refers to different colors; perhaps a dark outer/longer coat. Sometimes this refers to the length. Also referred to as "primitive".

Double Fleece

A fleece consisting of two year's growth.

Doupioni

A silk yarn reeled from two or more entangled cocoons and producing a coarse yarn Generally used in fabrics such as shantung or pongee. See "Reeled Silk".

Down Twist

This is one of the two terms that Alden Amos uses when discussing plying. This refers to an "S-Twist". Alden maintains that people get so hung up trying to remember whether an S-Twist is spun clockwise, that they lose track of process. It really doesn't matter whether your singles are spun S or Z, you just need to ply them in the opposite direction.

Down Wool

Allso called 'Hill Wool'. Wool of medium fineness produced by such breeds as the Southdown and the Shropshire. These sheep are distinguised by their fine and curly wool of short staple, which is especially adapted for making loose, rough, moss-like, felted, carded yars for the production of clothing. These wools are lofty and well suited for woolen. Much of the down wool runs 1/4 to 3/8 blood in quality. This can be a great wool for felting.

Drafting (or Drawing)

The process of blending, levelling, and drawing out the fibers from your drafting hand (usually your left) to your spinning hand (usually your right) to produce a fine sliver.

Drafting Triangle

The small triangle of fibers that are formed between your drafting hand and your fiber hand. This should never be longer than the fiber length. Also called a "drafting triangle".

Drape

The way a fabric hangs. Drape is affected by yarns, weave structure, and finish.

Drive Band

The cord that runs between the wheel and the flyer. A single-drive band is a circle and is used with the Scotch Tension wheels. A double-drive band is a figure-8 folded back on itself and loops over the flyer unit and the speed whorl.

Drafting

The process of drawing out the fibers so that twist can enter the fiber.

Drive Ratio

Ratio of wheel diameter to flyer whorl diameter (or bobbin whorl on a bobbin lead wheel). Governs how much twist you get in the yarn for each treadle.

To measure your wheel ratios, set up your wheel, tie a bright-colored piece of yarn to your flyer arm, and adjust the treadle until it is at the bottom of its movement. Slowly rotate the wheel, while counting the flyer revolutions until the treadle returns to it's original point. The bright yarn tied to the flyer arm just makes it easier to count.

Drop Spindle

A spindle that hangs freely from the fiber source (as opposed to a supported spindle). Probably so named by people who haven't added enough twist.

Drum Carder

A rotating drum, covered with carding cloth, used to card fibers. An example hand-cranked drum carder can be viewed on the Ashford site.

Dry Combing

Preparing wool for worsted spinning without any oil. Also referred to as "French combing".

Dry-Spun Flax

This is a term for spinning flax and mainly is a way of differentiating it from 'wet-spun flax'. In dry-spun flax, additional water is not added to the surface in spinning. It produces a hairier, less-attractive yarn.

Dull

A yarn or fiber surface lacking in lustre.

Dusting

The second step in commercial wool processing (after sorting). The purpose is to remove as much dirt and sand as is possible before scouring.

Dye

There are many application classes of dyes, including acid dyes, disperse dyes, reactive dyes, and natural dyes. Dyes may be generally divided into natural and synthetic types. Natural, or vegetative, dyes are obtained from berries, flowers, roots, bark and more. Synthetic dyes are chemical compounds.

Dye Activator

The recommended pure alkali powder for use with all reactive dyes on cotton and cellulose fibers. Also used to scour fabric along with Synthrapol.

Dyeability

The capacity of fibers to accept dyes.

Dye bath

The solution (usually water) containing the dyes, dyeing assistants and any other ingredients necessary for dyeing.

Dyed in the Wool

Fabrics or yarns where the fibers were dyed prior to processing.

Dyeing

The process of applying a comparatively permanent color to fiber, yarn or fabric by immersing in a bath of dye.

E

Eastern Pulled WoolWool is pulled from the skins after it has been loosened, usually be a depilatory. Pulled wool should not be confused with dead wool. Elasticity

The ability to return to its original length after being stretched or compressed. Wool has more elasticity than cotton, with finer wools stretching up to 30% of their original length.

Electric 'wheel'

A flyer on bearings driven by a small motor. Very compact, can be useful for people with limited use of legs. Very portable, can be battery powered.

End

A warp yarn.

English Combs

The multi-pitch (commonly 4-pitch) hand combs used in preparing top.

Evenness

This term refers to the uniformity of the fiber throughout the fleece.

Exhaustion

The amount of dye taken from the dye bath by the fiber, yarn or fabric being dyed. Also, the condition of the dyer at the end of the day.

F

FabricAny cloth woven or knitted from fibres. Fall Wool

Wool shorn in the fall following 5-6 months of growth. Fast Color

A dye which is stable to color destroying agents, such as sunlight, perspiration, washing, abrasion, and pressing.

Fellmongedring

The process of gathering wool from the fleeces of dead sheep.

Felt or Felting

Non-woven fabric made by layering thin sheets of carded wool fibers, then applying heat, moisture and pressure to shrink and compress the fibers into a thick matted cloth that will not ravel or fray.

Feltability

The degree to which fibers will consolidate by felting.

Felting

The matting together of fibres during processing or use.

Felting Property

The property of wool and some other fibers to interlock with each other to create felt. Felting is caused by the directional friction effect of scales on the fiber surfaces. The factors involved in felting are the fiber structure, the crimp of the fibers, the ease of deformation of the fiber and the fiber's power of recovery from deformation.

Fiber

The fundamental component used in making textile yarns and fabrics. Fibres are fine substances with a high ratio of length to thickness. They can be either natural or synthetic (man-made). Natural fibres are of animal origin (wool, mohair, etc.) or vegetable origin (cotton, linen, etc.) or mineral origin (asbestos). Synthetic fibres are produced from naturally occurring material, mainly wood pulp or cotton lint, and the most commonly used example of this form of fibre is rayon. Manmade fibres are produced directly by the polymerisation of synthetic chemicals at present obtained as by-products of the petro-chemical industry: typical examples are nylong and polyester.

Fiber Fineness

The mean fiber diameter which is usually expresses in microns.

Fiber Length

The staple length of the fiber. On combing wools, this is often 3-8 inches, on the down wools 1.5-3 inches. With cotton, it may be 1/4-1 inch long. Bast fibers, likes flax, may have a staple length of 36 inches.

Fiber Thickness

The average diameter of the fiber.

Filament

A fiber of indefinite or extreme length, some of them miles long. Silk is a natural filament, while nylon and polyester are synthetic filaments. Filament fibers are generally made into yarn without the spinning operation required of shorter fibers, such as wool and cotton. Filament yarns are smoother and more lustrous than spun yarns.

Fine Wool

The finest grade of wool -- 64's or finer, according to the numerical count grade OR wool with an 18 to 24 micron count. Also, the wool from any of the Merino breeds of sheep. Fine wools may have as many as 30 crimps per inch.

Finishing

This refers to additional steps used after the yarn is removed from the bobbin. See brushing and fulling

Flame Retardant

Any process which can improve the resistance of a fabric to burning.

Flammability

The ability of a textile to burn under specified test conditions.

Flannel

Traditionally, an all-wool fabric of plain or twill weave with a soft handle.

Flax

A slender, erect, annual plant (genus Linum having narrow, lance-shaped leaves and blue flowers, cultivated for its fiber and seeds. The fiber of this plant, manufactured into linen yarn for thread in woven fabrics.

Fleece

The wool from one sheep, either as it comes from the animal or after it is rolled into a bundle and tied.

Fleece Wools

Wools produced on farms in areas east of the Rockies, inclusive of those produced east of the Mississippi River.

Flicker

A hand tool that looks like a small hand card on a long handle. To use it, hold one end of a lock of wool in your left hand rested on your thigh and "flick" the tool up and down with your other hand catching the end of the fiber. This will open out the lock and make it easier to spin. It is recommended to wear a sturdy pair of jeans or place a leather pad on your left thigh.

Flyer

A rotating device that adds twist to the slubbing or roving and winds the stock onto a spindle or bobbin in a uniform manner.

Flyer Bearings

Holds the flyer, same material as used in wheel bearings

Folded Yarns

Another term for plied yarns.

Flyer Lead

A single band drives the flyer. The bobbin has an adjustable friction band to slow it. A well-known example of this would be the Ashford Traditional.

Follicle

The skin structure from which hair or wool fiber grows.

Footman

The vertical connection between the treadle and the crank

Formosul

Sodium formaldehyde sulfoxylate. It is the preferred discharge for silk and wool which requires steaming.

Frame Spinning

The manufacture of yarn by attenuating a sliver by means of rollers and then inserting twist by means of a flyer, a ring and traveller, or a cap. (A commercial term.)

Frame Wheel

The flyer is usually mounted above the wheel, which means less floor space is used. Also called a "castle wheel". A well-known example of this is Alden Amos' castle wheel.

Free Wools

Usually means wool that is free from defects, such as vegetable matter.

French Combing Wool

Wools that are intermediate in length between strictly combing and clothing. French combs can handle fine wools from 1.25:2.5 in. in length. Yarns that have been produced with the French combing method are combed dry; without oil added. (See Bradford Spinning.) The yarn is softer and loftier than the Bradford (worsted) yarn.

Fribby Wool

Wool containing an excessive amount of second cuts and/or sweat locks.

Frowzy Wool

A wasty, lifeless-appearing,dry, harsh wool, lacking in character. See "lofty".

Fugitive Colors

Dyes that fade, especially those that lose color relatively quickly when exposed to natural light.

Fulling

The operation of shrinking and felting a woolen fabric to make it thicker and denser. Also called "milling". You can also full woolen yarn to give you a lovely knitting yarn. (If you were going to weave with the same yarn, you wait until you had woven the fabric.)

Fulling Agent

A chemical, usually a surfactant, that acts as a lubricant during the process of fulling.

G

Garnetted YarnA yarn that has little bits ("garnets") of other fibers carded in. Usually the garnets are of a different color -- but they can also be from a different fiber. Gassed Yarns

Spun cellulose yarns passed over a heat source (or through a flame) to remove unwanted fibers on the surface. This gives a smoother surface but is not recommended at home. (Cellulose fibers are quite flammible.)

Gauge

A means of designating wool or mohair, primarily according to the fineness or length of fiber. There are three major ways to determine and refer to them: blood grade, Bradford count, and micron measure.

Gilling

A commercial process called "pin drafting" used to produce top fibers.

Ginning

The mechanical process that removes the cotton fibers from the seed.

Glauber's Salt

Sodium sulfate. An acid used in dyeing to help the protein fibers to take colors evenly (leveling). Used in acid dyeing.

Grade

A measurement used in knitted garments that reflects the size of the needles used to knit the garment. The larger the gauge, the smaller the needle the finer the knit.

Grading

Classification of the unopened or untied fleeces according to fineness, staple length, character, soundness, etc.

Gray Wool

Fleeces with a few dark fibers, a rather common occurrence in the medium wools produced by down or black-faced breeds.

Grease Wool

Wool in its natural condition as it comes from the sheep, either shorn or pulled. It contains a mixture of "suint" and wool fats. See also "scouring"

Great Wheel or Walking Wheel

(Usually) turned by hand, very large (e.g., 50" diameter), used for long draw on things like cotton (high twist). Instead of a flyer and bobbins, this wheel is a wheel-driven spindle. The Illinois State Museum site shows a Great Wheel.

Grist

The yards (or meters) per pound (YPP). So if you had a finished yarn that came up 890 YPP, one pound of yarn would equal 890 yards. The grist (or "count") may range from 300 yds/lb to 3,000,000 yd/lb for a single filament of silk (theoretically).

Guanaco

A protein fiber from the guanaco, a relative of the llama.

Guar Gum

An industrial gum used to thicken the burn out/devoré, paste during burn out processes. Won't break down under strong acid conditions.

Guard Hair

he long, stiff, usually coarse fiber which projects from the wooly undercoat of a mammal's pelt. Please see McColl's Darkroom in Cyberspace for drawings showing a close-up of fiber.

Gummy Wool

Scoured wool that still has some yolk in it.

Gutta

French for "resist", which forms a barrier on the fabric to create a pattern. may be water soluble, solvent soluble, or a heat fixable resin.

H

HabickAn instrument used during the Middles Ages to hold fabric under tension during its final preparation and dressing. It is roughly equivalent to the modern stenter rail. Hackles

The comb for dressing flax or hemp. Hackling

Cleaning the remaining woody particles and separation of the fibers. This is done by drawing the flax fibers through the hackles. Traditionally, there are three sets of hackles that are used to progressively process the fibers. The previous step would be 'rippling'.

Hair Fibers

Wool-like fibers from animals other than sheep, including the alpaca, llama, vicuna, cashmere goat, angora goat, angora rabbit and Bactrian camel.

Half-blood Wool

Designation of a grade classification immediately below the fine grade.

Hand or Handle

Refers to the actual feel of the wool; a good 'handle' has great resilience and softness, fineness, length, strength, and is pleasing to the touch.

Hand-washed Wool

Wool washed before it is shorn from the sheep.

Handspun

Yarns which are spun by hand using a spinning wheel or electric spinner.

Hank

A package of yarn from a reel, hopefully with the yardage and fiber content noted on a label. This may refer to a specified yardage, as in a hank of worsted yarn contains 560 yards, cotton and silk is 840 yards, and linen is 300 yards.

Hard Twist

A yarn with increased twist.

Harsh

A coarse, rough wool.

Heat Setting

The process of conferring stability upon fibres, yarns, or fabrics by means of steam or dry heat.

Heavy Wool

Wool that has considerable grease or dirt and will have a high shrinkage in scouring.

Hemp

The fiber from the plant Cannabis sativa.

Herringbone Twill

A broken twill weave composed of vertical sections which are alternately right hand and left hand in direction. The twill changes direction perfectly where the weave breaks, balancing the overall pattern of the fabric.

Hogget Wool

Hogget wool comes from sheep twelve to fourteen months old that have not been previously shorn. The fibre is fine, soft resilient, and mature, and has tapered ends. Hogget wool is a very desirable grade of wool and, because of its strength, is used primarily for the warp yarns of fabrics.

Hook

The device used to pull the lead through the wheel's orifice.

Homespun

In theory, this refers to rough, coarse, tweed-like fabric made with thick, uneven yarns and a plain weave. Obviously, not defined by a person who spends much time with good handspinners.

Hue

The pure spectrum colors commonly referred to by the "color names" - red, orange, yellow, blue, green violet.

Hungry Fine

A term used to describe a fine wool caused by poor nourishment as opposed to careful breeding. Please see McColl's Darkroom in Cyberspace for drawings showing a close-up of fiber.

J

Jacquard MechanismA mechanism, named after Joseph Marie Jacquard (1752-1834), which gives individual control of several hundred warp threads or knitting needles, enabling large figures designs to be produced.

I

InchwormA perjorative term used to describe tense spinners who "inch" their way through their fibers; often too close to the wheel oriface. Relax. This is supposed to be fun. Identification Test

Any procedure for determining kinds of fibers, yarn construction, fabric construction, or finish and coloring of textiles. Physical, chemical, microscopic and other methods may be used.

Impurity

Any undesirable extraneous material present in a fleece or textile product.

Indigo

A blue dye from a variety of plants in the Indigofera famiy. Commonly used as a vat dye on both cellulose and protein fibers.

J

JuteA vegetable bast fiber often used for basketry and course weavings.

K

KapokA vegetable seed fiber from the Kapok tree. Kemp

A white, straight, opaque, coarse, non-felting, in-elastic fiber having a thick central medulla with hollow inter spaces. It will not take a dye; hence, its presence in wool is most objectionable. Often found around the head and legs.

Keratin

A protein substance which is the chief component of wool fiber.

Knop

A "bunch" of fibers appearing along the length of yarn, giving a spot effect.

L

Lamb's WoolWool shorn from lambs, usually when they are less than 7-8 months old. It is soft and has spinning qualities superior to fleeces of similar quality produced on older sheep. Please see McColl's Darkroom in Cyberspace for drawings showing a close-up of fiber. Lanolin

Purified wool grease, chiefly a mixture of cholesterol esters. It is used in salves, cosmetic, grease paints, and ointments.

Lazy Kate

The device used to support full bobbins while plying. A fairly traditional design, involves two vertical posts that support the bobbins. Rather like a free-standing ladder. And example of this can be found on the LeClerc site. Another form, favored by Schacht, has the bobbins supported horizontally with the addition of a breaking cord to control the backspin. Now, Alden Amos favors a vertical support with the addition of leather washers to help slow down the backspin. At this time, there is no image available.

Lea

A form of measuring linen yarns in 300-yard increments and weighing one pound. A 4-lea skein would also weigh one pound but would be 1200 yards long.

Leader

This is the length of yarn attached to the center core of a bobbin or shank of a spindle to aid in starting your yarn.

Leas Ties

Also known as lees ties and lease ties. This is such an interesting term that pops in and out of textiles. I asked a longtime weaver which was correct. She said it wasn't so much correct but where you learned to weave. The fact that a term used in measuring linen yarns is "lea" makes me think leas ties came from that direction. So what are they? They are the short threads tied around hanks of yarn to help keep them from tangling while being washed, dyed, and stored. They are also the short threads tied around a warp to allow you carry it from the warping board/mill to the loom. They serve the same process of keeping the threads in order. They are tied by running a thread at right angles to the warp/hank and interweaving through and coming back at opposite angles. Kind of a series of sideways figure 8's.

Level

A dye term referring to even color.

Line Fleece

A fleece of wool midway between two grades in quality and length, which can be thrown into either grade.

Line Flax

Line fax is the long flax fiber that has been drawn off of the hackles. The finest preparation is often used for wet-spun linen, but line can also be dry spun.

Linen

Linen is the term used for fabric made from flax. Linen is generally favored for its fine, strong, cool-wearing properties. It is commonly cursed for it's wrinkling. In knitwear, linen is combined with other natural or synthetic fibers for improved strength and resiliency.

Llama

Llamas are a member of the camelid family fiber originally from South America. Please see McColl's Darkroom in Cyberspace for drawings showing a close-up of fiber.

Lock

A tuft or group of wool fibers that cling naturally together in the fleece.

Lofty Wool

Wool that is open, springy, and bulky in comparison to its weight. This type of wool is desirable.

Loom

A machine for producing cloth by the interlacing of two sets of threads substantially at right angles to each other.

Long Draw

This is a woolen-spinning technique. I'd encourage you to see Mablel Ross' spinning video.

Long Wool

Wool from such breeds as the Lincoln, Leicester, and Cotswold. It is large in diameter and up to 12:15 in. in length.

Low Wool

Wool of low 1/4 blood or lower in quality. Same as "coarse wool".

Lowland Wool

These breeds are characterized by producing wool that is generally coarser, and only wavy or quite straight, and of longer staple (over 4 inches). These wools are especially suited for the production of combed yarns, which are worked up into worsted fabrics.

Lustre

The natural gloss or sheen characteristic of the fleeces of long-wool breeds. Fibers with a lot of lustre is often referred to as "A HREF="#bright">bright".

Lye

Sodium hydroxide. Strong alkali used with vat dyes such as Indigo. Always add Lye to cold water!

M

MadderThe roots of Rubia tinctorum used in vegetative (natural) dyeing to get a red. Kind of a reddish brown.

Maiden

The name for the posts that support the flyer on a spinning wheel. Maiden and the base that supports them is called the mother-of-all.

Man-Made Fiber

A man-made fiber, e.g., viscose, rayon. Also known as "manufactured fiber".

Market Class

The grouping of animals according to the use to which they will be put, such as slaughter or feeder.

Marl Yarn

A yarn consisting of two or more single ends of different colors plyed together.

Matted Wool

See "Cotted".

Mawata

Silk coccons that have been simmered and opened onto a wooden frame.

Mercerisation

A treatment of cotton yarns or fabrics with caustic alkali, in which the fibers are swollen and stretched to increase the lustre in the finished product.

Mean Fiber Diameter

The average diameter (thickness) of a group of fibers from an animal.

Medium Wools

Usually 1/4, 3/8, and 1/2 blood wools, OR wools grading 50's to 62's, OR wools with an 24 to 31 micron count.

Medulla

The hollow, rounded cells which are found along the center of the main axis of a fiber. They may run continuously along the length of the fiber.

Medullated Fibers

Fibers having more meduIIa (center cell area); such fibers are coarse and uneven in diameter, harsh, low in elasticity. See also "kemp".

Mercerizing

Treatment used to increase luster and improve strength and dye affinity in cotton. The treatment consists of impregnating the fabric with cold concentrated sodium solution. Invented by John Mercer.

Micron

A micron is 1/25,400 of an inch. The most accurate way of determining wool grades. You might want to refer to the article "Understanding Micron Reports" by Angus McColl at the Yocum-McColl site.

Milling

The operation of shrinking and felting a woolen fabric to make it thicker and denser. Also call "fulling".

Miner's Head

An accelerating head used on walking (or great) wheels.

Mohair

Long, lustrous, silky white hair of the angora goat is stronger and more resilient than wool. It dyes more easily than any other specialty hair fiber and often comes in brilliant colors. It is blended with wool to add sheen and fluffiness to the wool or used alone to make soft, fuzzy sweaters, lofty novelty coatings and smooth worsted suitings with a somewhat wiry hand. Please see McColl's Darkroom in Cyberspace for drawings showing a close-up of fiber.

Moity Wool

Wool that contains straw or other, non-seed-or-burr vegetable matter.

Mordant

A material used to fix a dye in or on a substance, by combining with a dye to form an insoluble compound. Commonly used mordants are chrome, iron, aluminum, and tin.

Mother-of-all

The whole stand that supports the maidens, bobbin, and flyer.

Mungo

Wool fibers recovered from old and new hard worsteds and woolens of firm structure. The fibers are less than .5 in. in length, and owing to their reduced spinning and felting qualities, they are largely used in cheaper woolen blends. Mungo fibers are usually shorter than shoddy fibers.

Mushy Wool

Wool that is lacking in character, dry, and wasty in manufacturing.

N

NapSoft, fuzzy surface produced on a fabric by brushing it to raise the fiber. Npping

The process of raising fibres from the base structure of a fabric or felt. Natural Dye

Dye obtained from substances such as roots, bark, wood, berries, lichens, insects, shellfish and flowers.

Natural Fiber

Fiber obtained from animal, vegetable or mineral sources, as opposed to those regenerated or synthesized from chemicals. Please see Synthetic Fiber and Regenterated Fiber.

Navajo Ply

Basically a hand-crocheted loop used to create a thee-ply yarn.

Neps

Small knots of tangled fiber, usually consisting of short, dead or immature fiber, or caused by over-processing.

Nettle Fibers

The nettle class of fibers comprise of Common Nettle (Urtica dioica), China Grass (Urtica nivea), and Ramie (or rhea).

Niddy-Noddy

A traditional, low-tech way to wind a skein and measure yarn. This image of the elusive niddy-noddy shows a very good quality, homemade one. For the less crafty, or to dry damp skeins, consider making one out of 3/4 or 1" pvc.

Noble Comb

Used commercially in producing worsted yarn.

Noils

The short fibers that are removed from the fiber in the combing or top-making process. Wool noil is satisfactory for the manufacture of felts and woolens. Silk noil is sportier in appearance and created by short fibers, often from the innermost part of the cocoon.

Nostepenne

This deceptively simple-looking item is used to create a center-pull ball. Hatchtown Farms gives clear directions on how to use one.

Novelty Yarns

Yarns with an unusual character. Rather like marketing types referring to software bugs as "features", many spinners call distinctive yarns "novelty yarns". (The bias of the editor is showing.)

Numerical Count System

A wool grading system. It divides all wools into 14 grades, and each grade is designated by a number.

Nylon

The generic term for man-made fibers composed of polyamides derived from coal and petroleum. Characteristics: high strength, elasticity, low water absorption and quick-drying.

O

Off-sortsThe by-products of sorting -- shorts; britch wool, kemp, gray wool, stained wool, etc. Open Wool

Wool that is not dense on the sheep and shows a distinct part down the ridge or middle of the back. Usually found in the coarser wool breeds.

Opening

The second step in commercial wool processing (after sorting). The purpose is to open up the fleece in order that scouring will be more effective. Done with "dusting".

Orifice

Hole in end of flyer, directing the yarn to the bobbin, may also be a hook or pig's tail.

Overspun

See "Collapse".

P

Package DyeingPackage dyeing occurs after the wool has been spun into yarn. Peasant Combs

Single-pitch and 2-pitch hand combs used to produce a semi-worsted fiber preparation.

Pelt

A sheep skin with the wool attached.

Pick

In weavig, a weft yarn. In spinning, the process of opening out the fiber to help in the cleaning and processing. This process (picking) allows a lot of vegetable matter to drop out of fleece.

Picker

A mechanical device used to open fleece before carding. The swing picker looks, for all the world, out of something from an Edgar Allen Poe horror story. Not recommended for the faint-of-heart, children, or those who don't pay attention.

Piece Dyeing

Piece dyeing occurs after the cloth has been woven or knit, but only solid colors are possible

Pelt

The skin from a slaughtered sheep before the wool on it has been pulled or processed into a sheepskin.

Pencil Locked

A fleece with narrow staples or lock formation: indicates an open fleece that has less density and probably more vegetable matter. This type of lock formation is genetic and is passed on to offspring.

Picker

This is a rather terrifying tool used to help open out washed fleece prior to carding. Basically it is a crescent-shaped swing that rocks in a cradle. Between the base of the picker and the bottom of the swing, there are a series of nails that catch the fiber and open it out. This tool accomplishes much the same process as hand-picking your fiber -- but much faster. As with any machinery, use with extreme caution.

Picking

The process of opening fiber and/or removing foreign matter.

Pilling

The small collection of engtangled fibers on a fabric surface.

Pin-drafting

A system of drafting in which the fibers are oriented relative to one another in the sliver and are controlled by rolls of pins between the drafting rolls. It is primarily used for long fibers in the semi-worsted and worsted spinning systems.

Pina

The vegetable leaf fiber from the pineapple plant.

Pieces

The skirtings and other less-desirable pieces of wool removed from the fleece. (Australian term)

Pilling

The tendency of some yarns to form little balls of short, tangled fibers on the surface. This tendency can be reduced (or removed) by removing the short fibers (combing) or by adding additional twist.

Plain Wool

Wool lacking character with few crimps.

Plant Fiber

A fiber generated from a plant, e.g., cotton, flax.

Plied Yarns

Yarns produced by two or more singles have been twisted together.

Ply

A single unit of yarn. A 2-ply yarn would involve taking two singles and then plying them in the opposite direction they were originally spun. See "S-twist" and "Z-twist".

Plying

The process of taking multiple singles and twisting them back against themselves.

Polishing

Usually done on commercial sewing thread,the process involves burnishing the plied yarn.

Polyester

A manufactured fiber made from long-chain synthetic polymers. Characteristics: crease-resistance, quick-drying, great shape retention, high strength, abrasion resistance and easy care.

Pot Ash

Potassium Carbonate. A replacement for dye activator or soda ash.

Primaries

The three basic "hues". Ah, but which primary. The Painters Primaries include red, blue, and yellow. This is the palatte we learned in school. The Printers Primaries include magenta, cyan, and yellow. This is the palatte used for color printing. The Light Primaries include red, blue, and green. This is the palatte used on your computer screen.

Primitive

A fleece with both long and short fibers. See "double coated".

Production Sequence

Shearing, sorting, opening, cleaning, carding, drawing, possibly combing, possibly roving, twisting or spinning.

Protein Fiber

A fiber composed of protein, including such naturally occurring animal fibers as wool, silk, alpaca, llama and other hair and fur fibers.

Pulled Wool

Wool pulled from skins of slaughtered sheep. The wool is pulled from the skins after treatment of the fleshy side of skins with a depilatory. Pulled wool should not be confused with "dead wool".

Puni

A puni is a tighter-than-normal rolag traditionally used with cotton. Kind of. Check the Urban Spinner site for their directions on creating a puni.

Purebred

An animal of pure breeding, registered or eligible for registration in the heard book of the breed to which it belongs.

Purity

Refers to the absence of dark fibers, kemp or hair.

Q

QiviutDown undercoat fiber from the musk ox. Quality

Refers to the degree of fineness.

Quarter-blood Wool

One of the grades in the standards for wool.

R

RafiaA vegetable fiber produced from the rafia palm. Ramie

The bast fiber produced from the Asian urticaceous shrub Boehmeria nivea or Boehmeria tenacissima. Used to also be called 'rhea' or 'China grass'. The fiber is white, soft, lustrous and slightly coarser than flax (linen) when degummed and bleached. Ramie fabrics are strong, smooth and durable.

Range Wool

Wool produced under range conditions in the West or the Southwest. With the exception of Texas and California wools, it is usually classified as territory wool.

Raw Silk

Continuous silk containing no twist that has been drawn off of cocoons. The fibers are often un-degummed.

Raw Wool

Wool in the grease, as shorn from the sheep. Same as "grease wool".

Rayon

A generic term for man-made fibers composed of regenerated cellulose derived from trees, cotton and woody plants. Characteristics: high absorbency, bright or dull luster, pleasant feel or hand, good draping qualities, ability to be dyed in brilliant colors and superior strength.

Reclaimed Wool

Wool that is reclaimed from new or old fabrics.

Reeled Silk

A long strand made of silk reeled from a number of cocoons and not twisted or spun. See "Doupioni".

Regenerated Fiber

These are fibers created by modified natural fibers. The cellulose regenerated fibers include rayon and acetate. The protein-regenerated vegetable fibers include soybean (soylon), peanut (ardil), and corn (vicara). The protein-regenerated animal fibers include casein (aralac), gelatin, and albumin.

Rejects

Off-grades thrown to one side by the wool grader; fleeces with excessive black fibers, kemp, dead fibers, vegetable matter, etc.

Reprocessed Wool

Scraps and clips of woven and felted fabrics made of previously used wool. These remnants are garnetted; that is, shredded back into a fibrous state and used in the manufacture of woolens.

Resilience

The power of recovery to original shape and size after removal of the strain which caused the deformation. A fiber may possess this quality to spring back to its original state after being crushed or wrinkled. Resilience is sometimes referred to as memory.

Retayne

A cationic dye fixing agent. Used on cotton fabrics to improve wet fastness of direct dyes and to color paper pulp. Is helpful as an after treatment for reactive dyes where washing facilities are not adequate for complete washout, though tends to lower light fastness qualities.

Retting

This is the process in flax production that weakens the fibers in the flax plant. Several retting methods are used:

- Dew or Grass Retting. Small bundles of the uprooted flax plants are left outdoors for 3-5 weeks.

- Pond Retting. Small bundles are left submerged for 4-8 days. Many books refer to an unpleasant stench as a side effect of this process.

- Stream Retting. Small bundles are anchored in a body of moving water. This is the quickest and the cleanest of the processes.

These are cleaned and shredded into fibers again, and then blended to make utility fabrics. See also "shoddy".

Reworked Wool

Wool that has been previously used. Also called "shoddy" and "mungo".

Rippler

The coarse comb used for removing seeds from flax fiber. The next step would be 'hackling'. The preceeding step would be "scrutching".

Rippling

The process in flax production that removes the seed pods. The tool used is a 'rippler'. After this step of flax fiber preparation, the fibers are 'retted'.

Robust Wool

Wool possessing a strong hand and bulky nature.

Rolag

The cigar-shapped roll of carded fiber, losely rolled off of the hand cards, used as the fiber source when spinning woolen yarn.

Rooed

The process where fleece is plucked off of Shetland sheep during the spring. This works with Shetland fleece as the sheep produce a weak spot earlier in the season. Sometimes called rooing.

Roving

The soft strand of carded fiber that has been twisted, attenuated, and freed of foreign matter preparatory to spinning.

Run-out Fleece

A fleece that varies greatly in quality, lacks character, and carries a large percentage of britch wool and possibly kemp.

S

S-TwistSpinning clockwise. Traditionally, this is the direction "singles" are spun. If your singles have been spun S-twist, you would ply Z-twist, and then cable S-twist. Saxony Wheel

Three-legged 'standard wheel' featuring a side-by-side arrangement with the flyer to the left of the drive wheel.

Scales

Cuticle cells form a scale-like formation on the surface of the fiber, resembling shingles on a roof. These scales on the surface of the fiber open from base to tip, causing an interlocking or felting action when fibers are randomly mixed during processing. Please see McColl's Darkroom in Cyberspace for drawings showing a close-up of fiber.

Scotch Tension

A single band drives the flyer. The bobbin has an adjustable friction band to slow it. When tension on the yarn is released, the bobbin rotations is stopped by the break band and the flyer winds the yarn onto the bobbin. Because this only involves one simple adjustment, many 'beginner' wheels use Scotch Tension. A well-known example of this would be the Ashford Traditional.

Scouring

The process of washing or cleansing wool of grease, soil, and suint in a water/soap/alkali solution. When scouring is done commercially, a normal fleece goes through at least three washings. During the scouring process, a fleece may loose up to 50% of its original weight.

Scroop

The rustleing sound produced when some silk is compressed.

Scrutching

This is a mechanical operation which, by breaking and beating the retted flax straw, separates the textile fibres in the stem of the plant from the woody matter and the bark. The next step would be 'hackling'.

Sea Island Cotton

Finest of all cotton, very white and silk-like with staple of 1.5" or better. Before the American Civil War, this type of cotton was raised on the islands of the Carolinas and Georgia. No longer raised in the United States today, it is raised in Mexico and Central America and goes into fine, expensive dress goods and men's shirtings.

Second Cuts

Fribs, or short lengths of wool resulting from cutting wool fibers twice in careless shearing. An excessive number of second cuts decreases the average fiber length, and depreciates spinning quality. See "Noils".

Seedy Wool

Wool containing numerous seeds or an appreciable amount of vegetable matter.

Selvedge